易群,博士,教授,博士生导师

E-mail:yq20071001@163.com;yq20210901@wit.edu.cn

教育背景

2008.9–2013.6,太原理工大学,化学工程与技术,博士

2004.9–2008.7,金沙威尼斯欢乐娱人城,化学工程与工艺,学士

工作履历

2021.08-至今,金沙威尼斯欢乐娱人城,特聘教授(化工与制药学院院长,绿色化工过程教育部重点实验室副主任)

2015.11-2021.07,太原理工大学,教授(环境科学与工程学院副院长(挂职),太原理工大学CO2捕集封存利用研究中心主任)

2017.8-2018.8,The University of Sheffield (英国),访问教授

2014.1-2015.1,Curtin University of Technology (澳大利亚),访问学者

2013.7-2015.11,太原理工大学,讲师

课题组网址

http://xljk.ms-cloud.cn/

学术兼职

SCI期刊《Fuel》副主编(Associate Principal Editor),客座主编(Managing Guest Editor),石油化工高等学校学报编委;湖北省化学化工学会理事,山西省青年科技工作者协会理事、能源与环境组副秘书长,山西省能源环境领域技术与战略专家,山西省碳达峰碳中和科技专项行动-节能环保专家组成员,教育部/山东省/安徽省等科学技术奖函评专家,国家自然科学基金函评专家等。

学术成就、奖励与荣誉

主持国家自然科学青年、面上、联合基金项目,科技部重点研发计划子课题,山西省重点研发计划项目、中国工程院重大咨询项目课题等30余项;在能源环境化工领域Chem.Soc.Rev.,Appl.Cat.B-Environ.,等权威期刊已发表论文60余篇,申请/授权中国发明专利40余件,参与编写/出版著作和教材7部,教育部自然科学一等奖,侯德榜化工科学技术青年奖。获山西省高校青年学术带头人,山西省“三晋英才”,山西省自然科学优秀青年基金等人才计划支持。作为指导教师获山西省第十七届“兴晋挑战杯”大学生课外学术科技作品竞赛特等奖、第二届中国可再生能源学会大学生优秀科技作品竞赛一等奖、第十四届全国大学生节能减排社会实践与科技竞赛三等奖,第十七届挑战杯全国三等奖等。

科研团队

易群教授(团队负责人)团队共有10人,专职教师/科研人员7人,其中教授2人,副教授3人,讲师2人,博士学位率100%。团队同清华大学、东南大学、华北电力大学、英国谢菲尔德大学、加拿大阿尔伯塔大学等国内外知名院校建立了良好的合作关系和人才联合培养模式。近五年,团队共承担研发课题30余项,其中国家和省部级项目20项,累计进账1000余万元,获教育部自然科学一等奖1项,山西省科学技术一等奖1项,发表SCI学术论文80余篇(其中SCI一区论文40余篇),申报/授权国家发明专利30余项。

欢迎各位有志之士加入团队!

团队硕/博研究生名额充足,欢迎各位同学报考与咨询!(常年有效)

研究领域

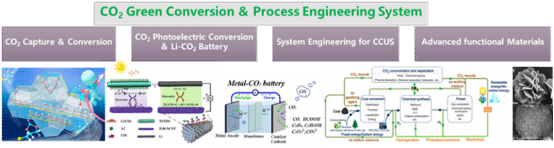

团队研究领域主要涉及大气污染物控制与利用,环境材料与化学和能源系统工程,涵盖CO2捕集与转化、CO2光电催化转化、CO2捕集/利用系统工程、CO2/NOx/SO2燃料电池、绿碳功能材料等研究方向,包括:

1)开发功能型CO2吸附分离材料简易、绿色、可控的组装合成方法;高性能、低成本、低能耗捕集的新型CO2/低质烃类/H2分离纯化功能材料的可控构筑;

2)立足于CO2捕集和资源化利用相结合的策略,开发适用于CO2低能耗捕集与转化的新型吸附-催化剂,高效捕集并催化CO2环加成反应制备环状碳酸酯及可降解聚碳酸酯等绿碳材料;

3)设计开发高选择性、高催化活性的CO2光/电催化剂材料;以CO2、SO2或NO2气体为基体,构建各类高效的金属-气氛电池体系;太阳能绿色驱动CO2原位转化合成醇醚燃料、低碳烯烃、异构烃和芳烃等高附加值燃料及化学品。

4)围绕开发的系列CO2捕集/转化材料与催化剂,开发设计适用于烟道气,弛放气、富碳燃料气等的碳富集分离/转化工艺;CO2连续合成聚碳酸酯类产品的反应器及其工艺包;创新开发设计能源系统CO2循环转化利用路径与方式,优化CO2捕集/转化利用能源系统环境效益和技术经济效益方案,从CO2源头-转化路径-减排节点-产品终端-系统优化控制的系统层面科学的、合理的实现CO2控制与转化全过程节能、节水、经济、环保的多元平衡和协同。

学术成果

部分代表性论文:

1. YiQun, Li Wenying*, Feng Jie, Xie Kechang. Carbon cycle in advanced coal chemicalengineering. Chem. Soc. Rev., 44:5409-5445, 2015.(SCI,一区/Q1,IF= 54.56)

2. GongMinhui, Yi Qun*, Huang Yi, Wu Guo-sheng, Hao Yanhong, Feng Jie, Li Wenying*.Coke oven gas to methanol process integrated with CO2recycle forhigh energy efficiency, economic benefits and low emissions. Energy Convers.Manage., 133:318-331, 2017.(SCI,一区/ Q1,IF= 9.71)

3.Yi Qun; Liu Tingting; Wang Xingbao; Shan Yuanyuan; Li Xiangyuan; Ding Minggong;Shi Lijuan*; Zeng Hongbo*; Wu Yucheng*; One-step multiple-site integrationstrategy for CO2capture and conversion into cyclic carbonates underatmospheric and cocatalyst/metal/solvent-free conditions, Appl. Catal., B, 283:119620. 2021. (SCI,一区/Q1, IF=19.50)

4.Yi Qun,Wu Guosheng,Gong Minhui,Huang Yi,Feng Jie,HaoYanhong,Li Wenying*. A feasibility study for CO2recycleassistance with coke oven gas to synthetic natural gas. Appl. Energy,193:149-161, 2017.(SCI,一区/ Q1,IF= 9.75)

5.Yi Qun, Zhao Yingjie, Huang Yi, Wei Guoqiang, Hao Yanhong, Feng Jie, WilliamNimmo*, Li Wenying*. Life cycle energy-economic-CO2emissionsevaluation of biomass/coal, with and without CO2capture and storage,in a pulverized fuel combustion power plant in the United Kingdom. Appl.Energy. 225:258-272, 2018.(SCI,一区/ Q1,IF= 9.75)

6.Huang Yi, Yi Qun*, Kang Jingxian, Zhang YaGang, Li Wenying*, Feng Jie, XieKechang. Investigation and optimization analysis on deployment of China coalchemical industry under carbon emission constraints. Appl. Energy, 254:113684.2019.(SCI,一区/ Q1,IF= 9.75)

7.Huang Yi, Yi Qun*, Wei Guoqiang, Kang Jingxian, Li Wenying*, Feng Jie, XieKechang. Energy use, greenhouse gases emission and cost effectiveness of anintegrated high–and low–temperatureFisher–Tropsch synthesis plant from a lifecycle viewpoint.Appl. Energy, 228:1009-1019. 2018.(SCI,一区/ Q1,IF= 9.75)

8.Yi Qun, Gong Minhui, Zhang Jilong, Huang Yi, Feng Jie, Li Wenying*. Processdevelopment of coke oven gas to methanol integrated with CO2recyclefor satisfactory techno-economic performance. Energy, 112: 618-628, 2016.(SCI,一区/Q1,IF= 7.15)

9.Yi Qun, Feng Jie*, Wu Yanli, Li Wenying*. 3E (energy, environmental, andeconomy) evaluation and assessment to an innovative dual-gas polygenerationsystem. Energy, 66: 285-294, 2014.(SCI,一区/ Q1,IF= 7.15)

10.Yi Qun, Li Wengying*, Zhang Xiaochao, Feng Jie, Zhang Jilong*, Wu Jinjing.Tech-economic evaluation of waste cooking oil to bio-flotation agent technologyin the coal flotation industry. J. Clean. Prod., 95:131-141. 2015. (SCI,一区/Q1, IF=9.30)

11.Yi Qun, Zhang Jilong, Zhang Xiaochao, Feng Jie, Li Wenying*. Synthesis of SO42−/Zr-SBA-15catalyst for the transesterification of waste cooking oil as a bio-flotationagent in coal flotation. Fuel, 143:390-398, 2015. (SCI,一区/ Q1,IF=6.609)

12.Hao Yanhong,Huang Yi,Gong Minhui,Li Wenying*,Feng Jie,Yi Qun*. A polygeneration from a dual-gas partial catalyticoxidation coupling with anoxygen-permeable membrane reactor,Energy Convers. Manage.,106:466-478, 2015.(SCI,一区/ Q1,IF= 9.71)

13.Qin Zhifeng; Zhao Yingjie; Yi Qun*; Shi Lijuan*; Li Congming; Yan Xiaoliang;Ren Jun; Miao, Maoqian; Xie Kechang; Methanation of coke oven gas over Ni-Ce/γ-Al2O3catalyst using a tubular heatexchangereactor: Pilot-scale test and process optimization, Energy Convers. Manage.,204: 112302. 2019.(SCI,一区/ Q1,IF= 9.71)

14.Usama Mohamed; Zhao Yingjie; Huang Yi; Cui Yang; Shi Lijuan; Li Congming;Mohamed Pourkashanian; Wei Guoqiang; Yi Qun*; William Nimmo*; Sustainabilityevaluation of biomass direct gasification using chemical looping technology forpower generation with and w/o CO2capture, Energy. 205: 117904. 2020.(SCI,一区/Q1,IF= 7.15)

15.Shi Lijuan; QiKai; Wu Haonan; Li Jie; Qiu Mingyue; Deng Cunbao; Yi Qun*;In-situ amino-functionalization of zeolitic imidazolate frameworks forhigh-efficiency capture of low-concentration CO2from flue gas.Fuel,298: 120875, 2021. (SCI,一区/ Q1,IF= 6.609)

16.Zhao Yingjie; Zhang Yuke; Cui Yang; Duan Yuanyuan; Huang Yi; Wei Guoqiang;Usama Mohamed; Shi Lijuan; Yi Qun*; Pinch combined with exergy analysis forheat exchange network and technoeconomic evaluation of coal chemical loopingcombustion power plant with CO2capture; Energy, 238: 121720, 2022.(SCI,一区/Q1,IF= 7.15)

17.Zhou Huan; Zhang Zheming; Yi Qun*; Wei Guoqiang*; Zhao Yingjie; Zhang Yuke;Huang Zhen; Zheng Anqing; Zhao Kun; Zhao Zengli; Reactivity investigation onchemical looping gasification of coal with iron-manganese based oxygen carrier.Fuel,307: 121772, 2022.(SCI,一区/Q1,IF= 6.609)

18.Zhou Huan; Yi Qun*; Wei Guoqiang*; Zhang Yuke; Hou Yalei; Huang Zhen; ZhengAnqing; Zhao Zengli; Li Haibin; Reaction performance and lattice oxygenmigration of MnFe2O4oxygen carrier in methane-carbondioxide reaction system, Int. J. Hydrog. Energy, 45:30254-30266. 2020. (SCI,二区/ Q1,IF=4.939)

19.Usama Mohamed; Zhao Yingjie; Yi Qun*; Shi Lijuan; Wei Guoqiang; William Nimmo*;Evaluation of life cycle energy, economy and CO2emissions forbiomass chemical looping gasification to power generation. Renew.Energ., 176:366-387, 2021. (SCI,一区/Q1,IF= 8.0001)

20.Zhang Yu-ke, Zhao Ying-jie, Yi Qun*, Wei Guo-qiang*, Shi Li-juan, Zhou Huan;NiO/κ-CeZrO4functional oxygen carrierswith Niδ+and oxygenvacancy synergy for chemical looping partial oxidation reforming of methane.Fuel Process. Technol.,219: 106875, 2021. (SCI,二区/ Q1,IF=4.982)

部分专利:

ZL201811542746.X;

ZL201711269070.7;

ZL201410086174.4;

ZL201410086181.4;

ZL201410086182.9;

ZL201310464470.9;

ZL201310445921.4;

ZL201010584428.7等。